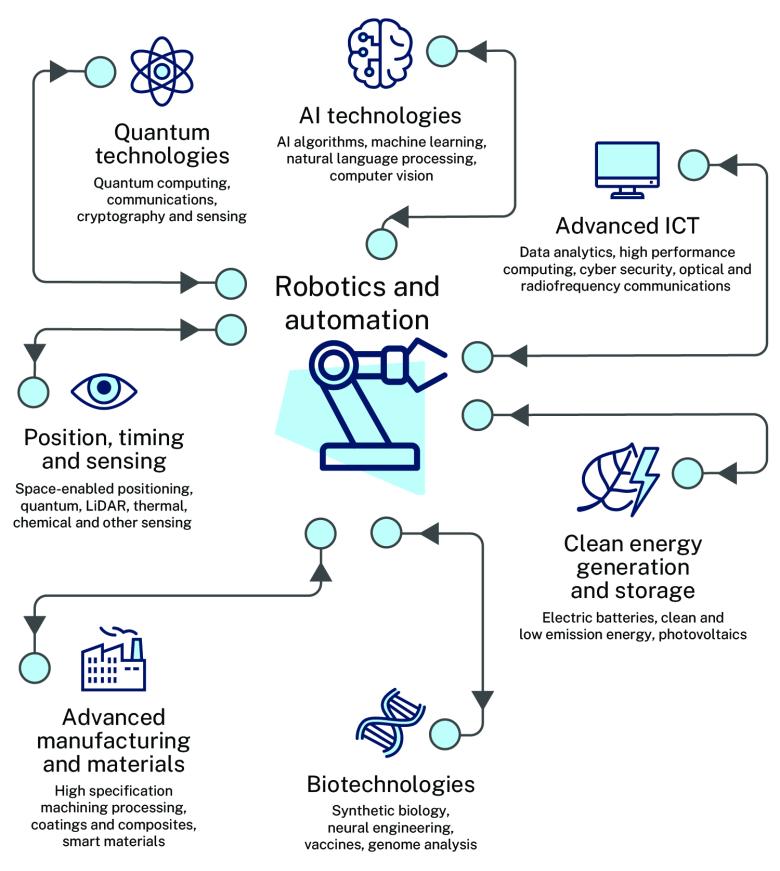

In the years ahead, national and global trends will shape the future of Australia’s economy and society. These include climate change, an ageing population, geopolitical risks, labour market pressures and stagnant productivity. Robotics and automation technologies will be critical to Australia’s response, as well as growing our economic diversity and building a Future Made in Australia.

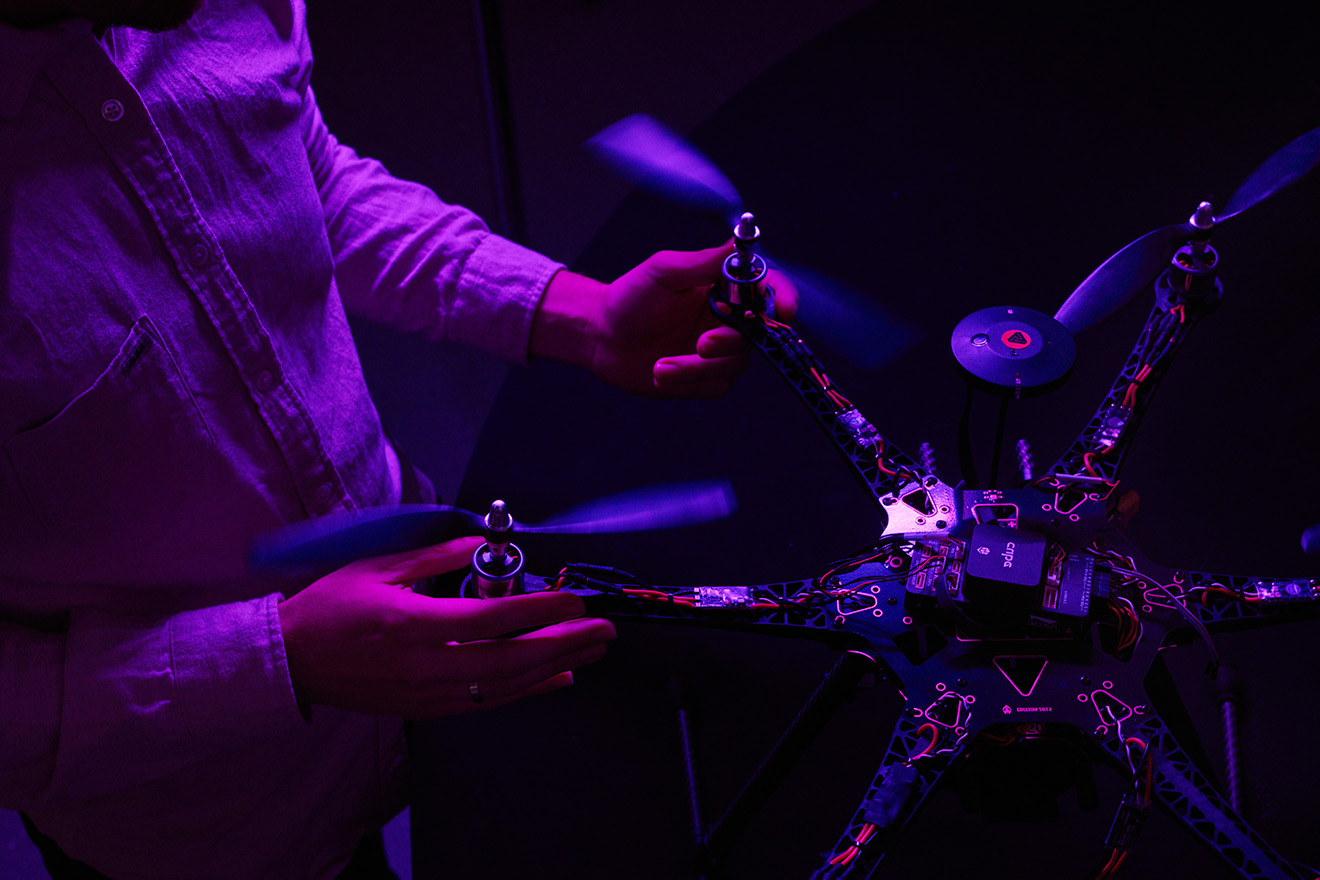

Robotics and automation will transform industries and reshape work processes on a global scale, as they have already done over the preceding decades. For many years, we’ve used robots in mines, logistics and manufacturing assembly lines to complete tasks that need precision or are repetitive or dangerous. Advanced robotics are now changing how people engage with technology at work, improving workplace safety and creating new jobs. This will continue as robotics and automation technologies become more affordable, effective and common in workplaces throughout Australia.

Internationally, developing and adopting robotics and automation technologies has been critical for boosting productivity and raising the competitiveness of industries. Recent advancements in AI, component technologies and robotic design are improving the rate and benefits of development and adoption globally. This momentum is already visible in Australia’s robotics industry. Local robotics companies were worth about $18 billion in annual revenue in 2021, up from $12 billion in 2018 (Robotics Australia Group 2022).

In Australia, productivity growth has slowed to 1.2% per year in the 20 years to 2021–22 – the lowest level in 60 years (The Treasury 2023a). The Productivity Commission’s 5-yearly Productivity Inquiry Report and the Treasury’s Intergenerational Report highlight the need for investment in new technologies to improve productivity (The Treasury 2023b; Productivity Commission 2023). Automation, including robotics, is predicted to increase annual productivity growth in Australia by 50% to 150%. These technologies have the potential to add a further $170–600 billion per year to GDP by 2030 (Taylor et al. 2019).

Australia has strong robotics expertise, renowned academic institutions and local capability in areas such as field robotics. Despite these strengths, the lack of a mature and well-coordinated supply chain for locally made solutions means we risk missing many of the opportunities these technologies present. Australia faces barriers in commercialising and scaling up our innovations, preventing us from taking full advantage of our leading research capability. These include the rationing of investment capital, high upfront costs needed to develop robotic solutions, limitations in our supply chains and our geographic isolation. Many Australian industries lag in adopting robotics technologies, which means many businesses are not tapping into the benefits these technologies can deliver.

Acting now to address these barriers will support revitalising Australia’s economy by growing national manufacturing capabilities and help to address labour and skills shortages. Robotics and automation technologies will also play a role in supporting Australia’s transition into a renewable energy superpower and net zero economy. The increased development and adoption will allow businesses to become more globally competitive, strengthen onshore supply chains and create safer work environments for Australians.

The Australian Government has already recognised the importance of revitalising sectors across our economy through critical technologies such as robotics. To support this effort, the government has the $15 billion National Reconstruction Fund (NRF). The NRF will make targeted investments to help Australia capture new, high-value market opportunities to diversify and transform our industries and strengthen our economy. A priority area for NRF investment is enabling capabilities. This concerns manufacturing technologies and products, including robotics, that support advancing Australia’s industrial capability. How companies adopt robotics and automation technologies will contribute to their competitiveness across all NRF areas.

The government is also supporting industry through the Industry Growth Program (IGP). The program assists innovative small and medium-sized enterprises (SMEs) and startups in their most challenging development phase. Finally, the Future Made in Australia agenda will support investment in modernising and digitising our industries to revitalise our advanced manufacturing base and onshore supply chains.

Building on these priorities, the National Robotics Strategy establishes a shared vision, goals and objectives for Australia, informed by extensive national consultation. The strategy shows the immense potential for Australian industries throughout the economy to benefit from robotics and automation technologies. The strategy seeks to use our strengths for Australian industries are responsibly developing and using robotics and automation technologies to strengthen competitiveness, boost productivity and support local communities.

Robotics and automation at the global frontier

Germany

Germany is one of the world’s major manufacturing powerhouses, partly because of its leadership in developing and adopting robotic and automation technologies. Germany’s manufacturing industry has been a leader in robotics and automation for decades. It has deployed more robots than any other country in Europe and is a leading innovator in developing industrial robots (IFR 2023c). This means that German manufacturers have been able to operate domestically rather than outsourcing to overseas competitors who have lower labour costs. By innovating and incorporating new technologies, Germany has improved the cost competitiveness of its manufacturing.

Japan

Japan is a leader in robot production, producing 45% of the global supply of industrial robots (IFR 2023a). Japanese companies have been at the forefront of robotics and automation production and adoption for decades. Adopting these technologies in industrial processes has been a critical factor in Japan’s economic success. Japan is also turning to robotics and automation to address barriers posed by their rapidly ageing population. While not without its issues, efforts in nursing homes have promoted more flexible work and improved staff retention.

United States

The United States is one of the world’s top food producers and exporters and is a leader in adopting new technologies in agriculture. Robotics and automation have improved productivity in the sector, including through more reliable monitoring and management of natural resources. Greater control over production, distribution and storage has resulted in increased efficiencies, lower prices and reduced environmental impacts (United States Department of Agriculture 2023).

China

China has been the largest industrial robot market for nearly 10 years, and in 2022 accounted for 52% of the world’s industrial robot installations (IFR 2023b). These robots, a mix of imported and locally produced technologies, are used in electronics, automotive and other manufacturing activities. This has helped China become the world’s largest manufacturer, including of electric vehicles, and address trends such as skills shortages and an ageing population.

Robotics and automation in Australia

Robotics and automation technologies have the potential to generate real social, economic and environmental benefits for Australia. We have unique advantages that will allow us to capture these benefits, such as our diverse landscape, education and training system and research capabilities.

Australia has an emerging robotics and automation industry that is growing in size and influence. In 2018 and 2022, industry peak body Robotics Australia Group released ‘Robotics Roadmaps’ for Australia. These showed the breadth of expertise in Australia and helped raise the profile of cutting‑edge Australian capabilities.

Many Australian industries have already adopted robots to work alongside humans to create safer and more productive workplaces. Robots are used in Australian underground mines, assembly lines and in dangerous settings like emergency response operations. Increasingly, medical professionals use robots to improve diagnosis, treatment and rehabilitation, as well as accuracy and patient recovery from invasive surgeries.

In agriculture, field robots support crop and livestock monitoring, and autonomous farming technologies increase crop yields and reduce pesticide use. The advanced manufacturing sector relies on automation to scale and export at a vastly increased level than what would otherwise be possible. Now, robotics and automation technologies are helping our nation transition to net zero, allowing us to install and maintain renewable energy infrastructure on a large scale.

Australia has strong research expertise and growing local capability to continue producing innovative robotic solutions. Field robotics is a particular opportunity for Australia. We have the research and development (R&D) expertise, local market and potential for high growth through global exports. In 2023, Australian research in robotics and related fields ranked in the top 10 countries globally for quality of research. We are 4th in additive manufacturing, 5th in data analytics and autonomous underwater vehicles, 6th in autonomous systems operation technology and 8th in advanced robotics (ASPI 2023). In addition, 3 Australian universities rank in the top 50 globally for robotics research publications (ASPI 2023).

Growing a sustainable robotics ecosystem will depend on the success of Australia’s robotics and automation R&D and commercialising these technologies. However, researchers and startups can face barriers to commercialisation. Attracting early-stage and long-term capital are barriers because of the upfront expense of robotics and automation hardware. Australia is also not a large-scale manufacturer of many robotics components, meaning industry and developers need to import from overseas suppliers. Building Australia’s domestic manufacturing capability will help address these issues by allowing access to secure, reliable and cost-effective robotics and automation technologies.